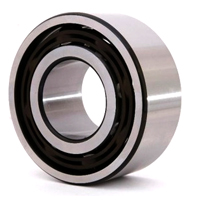

Angular contact ball bearing: It can bear both radial and axial loads. Can work at higher rotation speed. The larger the contact Angle, the higher the axial carrying capacity. High precision and high speed bearings usually take 15 degrees of contact Angle. Under axial force, the contact Angle will increase.

The Angular contact ball bearing is of the following types: 7000C (∝=15°), 7000AC (∝=25°), and 7000B(∝=40°).

Angular contact ball bearing accuracy class includes dimensional tolerance and rotation accuracy. The precision from low to high is denoted as P0(ordinary), P6(P6X), P5, P4, P2.

Product features

1. Bearings for general assembly

General assembly bearings are specially processed. When bearings are installed close to each other, any combination can achieve the established internal clearance or pre-tightening, and the average load distribution, without the use of gaskets or similar devices.

Paired bearings are used in: when the load carrying capacity of a single bearing is insufficient (using channeling configuration) or when to bear a combined load or axial load acting in two directions (using back-to-back or face to face configuration).

2.The basic design of bearings (can not be used as general assembly), for the configuration of a single bearing

The basic design of single-column angular contact ball bearing is mainly used in configurations with only one bearing per position. Its width and protrusion are common tolerances. Therefore, it is not appropriate to install two single-column Angular contact ball bearing close together.

Main uses

Single angular contact ball bearing: machine tool spindle, high frequency motor, gas turbine, centrifuge, small car front wheel, differential pinion shaft

Dual angular contact ball bearing: oil pumps, Roots blowers, air compressors, all kinds of transmission, fuel injection pumps, printing machinery

|